In the global horticulture procurement market, understanding the manufacturing process of pots is key to ensuring product quality and customer satisfaction. For B2B buyers, a clear grasp of the production stages and terminology differences across regions can help them select suitable suppliers and ensure that purchased products meet market demands. Hale Planter, specializing in ODM and OEM services, is dedicated to meeting the personalized needs of large-scale retailers and small-batch customers worldwide with high-quality ceramic pot products.

This article provides a detailed overview of the pot manufacturing process for buyers, covering important topics such as terminology variations, leading global manufacturers, production stages, and key considerations for procurement.

1. Various Terms for Pots and Global Preferences

In different countries and regions, pots are referred to by various terms, reflecting cultural preferences and market inclinations. Knowing these synonyms can help buyers communicate more effectively with suppliers and customers worldwide. Here are some commonly used terms for pots and their regional usage preferences:

| Term | Primary Regions | Description |

|---|---|---|

| Flower Pot | USA, UK, Australia | The most common term, widely used for both garden and indoor decoration. |

| Plant Pot | UK, Europe | A more general term, suitable for planting and decorative purposes. |

| Garden Pot | USA, Europe | Refers to pots typically for outdoor use, ideal for garden decor. |

| Planter | North America, Europe | Often refers to larger pots or containers, mainly for outdoor use. |

| Container | Asia, South America | A broad term for any planting container, suitable for a range of plants. |

Understanding these terms can enhance buyers’ ability to describe and market products in specific regions. For instance, “Planter” is more common in North America, whereas “Plant Pot” is widely used in Europe.

2. Top Five Ceramic Pot Manufacturers Globally and Their Signature Products

Worldwide, several well-known ceramic pot manufacturers are distinguished by their craftsmanship and unique designs. Here are five leading manufacturers and their representative products:

1.China – Fengxi Ceramic Factory, Chaozhou, Guangdong

Signature Product: Hand-Painted Succulent Ceramic Flower Pots

Features: The Fengxi area in Chaozhou, Guangdong, is one of China’s key ceramic production hubs, particularly famous for producing small, hand-painted ceramic flower pots for succulents. Known for their delicate craftsmanship, intricate designs, and vibrant colors, these pots are popular worldwide, especially for indoor décor and small plants.

2.Italy – Deroma

Signature Product: Classic Italian Terra Cotta Pots

Features: Deroma is one of Europe’s largest terra cotta flower pot manufacturers, known for its durability and classic Italian style. Deroma’s pots are widely used in outdoor gardening and are well-suited to high-end markets in Europe and the Americas. The natural terra cotta material and minimalist design make them ideal for outdoor landscaping.

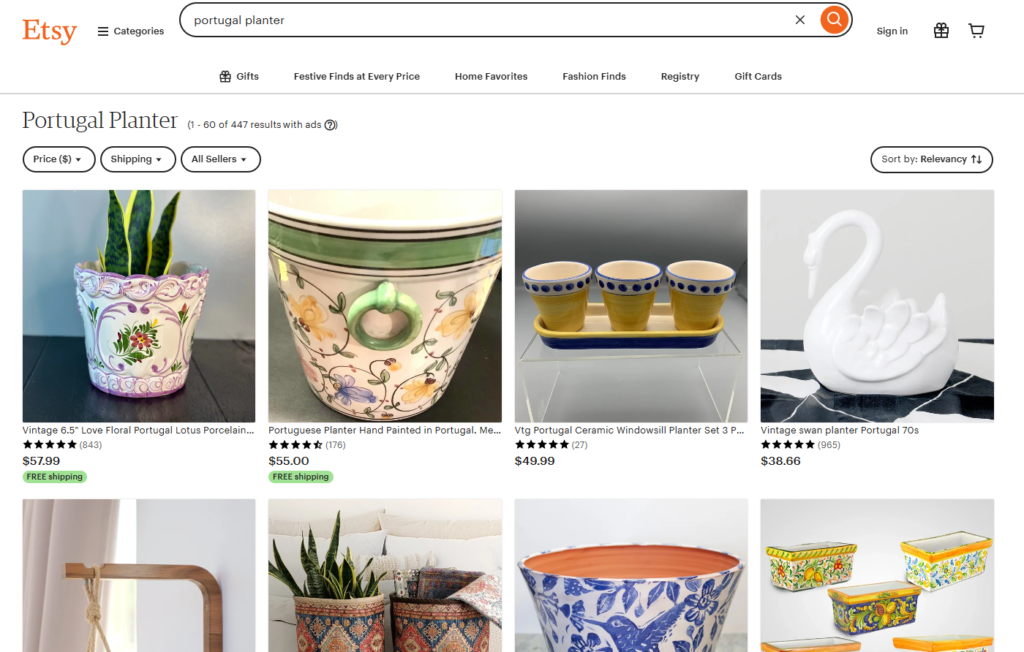

3.Portugal – Grehom Ceramics

Signature Product: Hand-Carved Ceramic Flower Pots

Features: Grehom Ceramics, based in Portugal, is known for its high-end, hand-carved ceramic pots, which feature unique designs and exquisite craftsmanship. These pots cater to the high-end home and commercial décor markets, appealing to customers seeking individuality, especially in premium retail markets across Europe and North America.

4.Turkey – Ege Ceramic

Signature Product: Vintage Glazed Ceramic Flower Pots

Features: Ege Ceramic from Turkey is renowned for its traditional craftsmanship and vintage designs, often featuring intricate glazed finishes that result in smooth surfaces and rich colors. Ege’s flower pots are suitable for both indoor and outdoor use and have a distinct Turkish flair, making them highly popular in European and Middle Eastern markets.

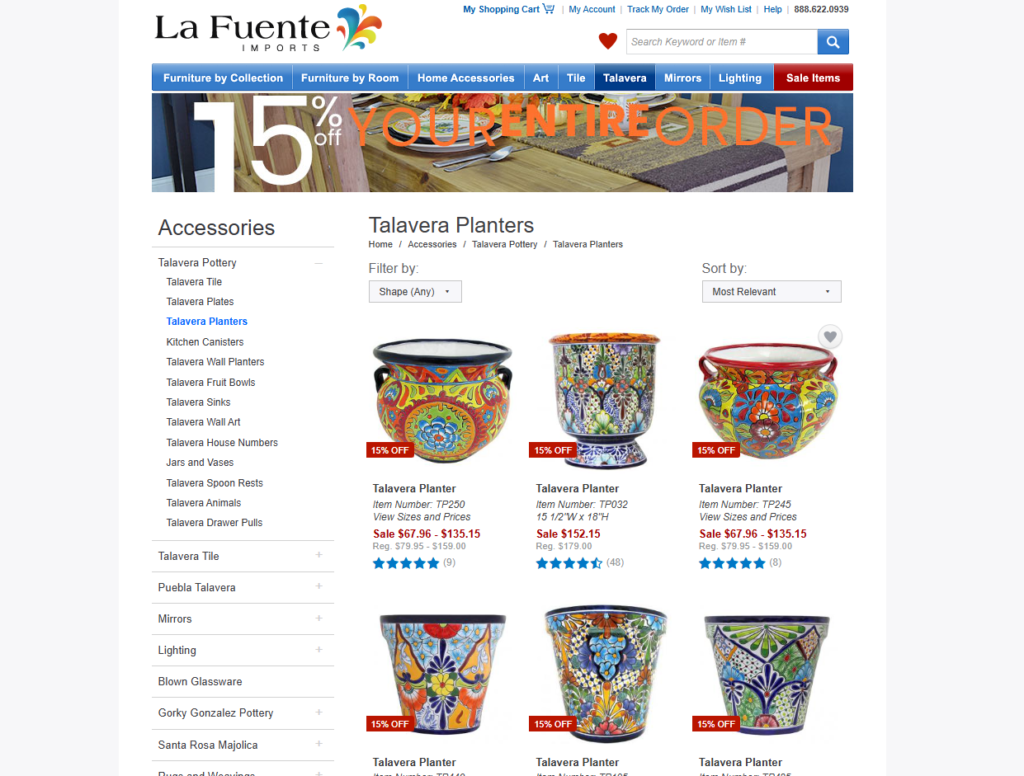

5.Mexico – Talavera Pottery

Signature Product: Hand-Painted Ceramic Flower Pots

Features: Talavera Pottery is a well-known Mexican ceramic factory famous for its hand-painted ceramic pots. Each piece reflects Mexican cultural heritage with vibrant colors and unique patterns, making them particularly appealing for gardens and interior décor. They hold a distinct place in the American market for their cultural aesthetic and uniqueness.

These factories represent the highest standards in global ceramic pot manufacturing, each offering distinctive styles and strong market positioning.

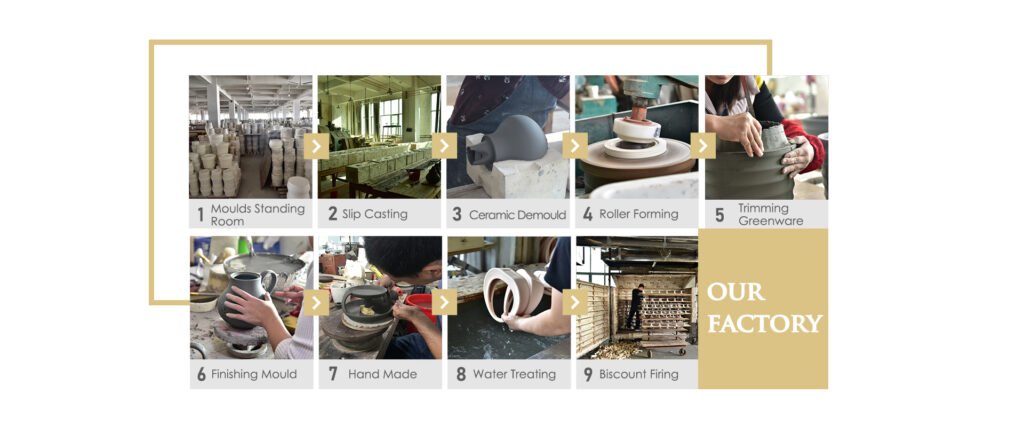

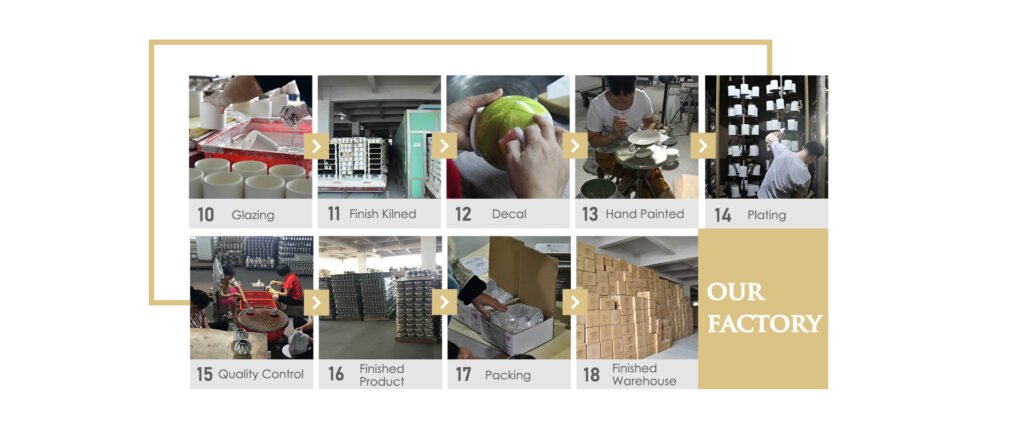

3. Manufacturing Process of Ceramic Pots

The pot manufacturing process involves multiple stages, from selecting raw materials to final product inspection. Each step is crucial to ensuring quality and durability. Here’s a typical ceramic pot manufacturing process:

1.Preparation of Raw Materials

- Material Selection: Common materials include clay, terracotta, and porcelain. The choice of material depends on the intended use and design style.

- Mixing and Formulation: Selected clay is mixed with water and other additives for a uniform texture.

2.Shaping

- Casting: Suitable for complex shapes, using molds to cast the clay.

- Hand Throwing: Used for custom products, where artisans shape the clay on a pottery wheel.

- Press Molding: Clay is pressed into molds to form the basic pot shape.

3.Drying

- Air Drying: Shaped pots need to air dry in a ventilated area to prevent cracks due to uneven moisture evaporation.

- Heated Drying: For faster production, low-temperature drying methods can be applied.

4.Bisque Firing

Low-Temperature Firing: Initial firing at 800-900°C to harden the clay and remove moisture.

5.Glazing

- Glaze Application: Based on design requirements, glaze is evenly applied to the pot surface, impacting the pot’s final appearance.

- Drying: After glazing, pots undergo a brief drying period to ensure the glaze adheres properly.

6.Glaze Firing

High-Temperature Firing: The second firing, typically above 1200°C, melts the glaze to create a smooth, waterproof surface. After glaze firing, the pot has a glossy finish and improved durability.

7.Quality Inspection and Packaging

- Inspection: Includes checks on appearance, strength, and size to ensure all pots meet quality standards.

- Packaging: Pots are packed per client requirements, with protective materials to prevent damage during transit.

4. Key Considerations When Procuring Ceramic Pots

For B2B buyers, several critical factors need to be considered when procuring ceramic pots to ensure the products meet market demands and quality expectations. Here are some key points:

1.Material and Craftsmanship

- Material Durability: Verify that the supplier uses materials suited to the pot’s intended environment, such as weather-resistant materials for outdoor pots.

- Consistency in Craftsmanship: Review the supplier’s manufacturing process to ensure stable quality, especially for bulk orders.

2.Quality Assurance and Certification

- Inspection Standards: Confirm that the factory has systematic quality inspection processes to ensure batch-to-batch consistency.

- Certification Requirements: Different markets may have specific environmental or quality certifications for ceramic products, such as CE certification.

3.Packaging and Logistics

- Protective Packaging: Ensure suppliers offer adequate packaging protection to prevent damage during transport.

- Logistics Efficiency: Confirm that suppliers can efficiently arrange logistics to meet delivery deadlines.

4.Reliability of the Supply Chain

- Production Capacity: Ensure suppliers have sufficient production capacity, especially for large ODM orders.

- After-Sales Support: Evaluate the supplier’s after-sales service to ensure timely assistance if any quality issues arise.

Why Choose Hale Planter?

Hale Planter provides customized pot manufacturing solutions for B2B buyers, meeting diverse global market demands. Our products stand out in quality, design, and sustainability, making them ideal for large retail chains and small-batch buyers alike.

- Large-Scale ODM: We support large retail chains with bulk custom orders, offering comprehensive design and production services.

- Small-Batch OEM: We provide highly personalized design and packaging services for small-batch customers.

- Sustainable Manufacturing: We are committed to using eco-friendly materials and low-emission production methods, contributing to sustainable development.

Conclusion

The manufacturing process of pots is intricate and detailed, making it essential for B2B buyers to choose reliable suppliers. Hale Planter is dedicated to providing high-quality ceramic pots for global buyers, offering full support in design, production, packaging, and delivery. We hope this article provides valuable insights for buyers, helping them make more informed purchasing decisions.