What is Terracotta?

The term Terra-cotta comes from the Italian dictionary meaning “Baked-earth,” ceramic Pottery. It is made out of a fairly coarse, porous type of clay that is high in iron oxides. Terracotta clay is easy to sculpt into various products such as vases, kitchen utensils, tile, planters, sculptures, bricks, etc. Once shaped, the dry clay is baked in a kiln or atop combustible material in a pit at a typical firing temperature of around 1,000 °C (1,830 °F), though in historical and archaeological cases, it may be as low as 600 °C (1,112 °F). After the baking part, the glaze has been applied to the product by which it gets its red color, although the actual raw clay can be brown, maroon, green, or red. Such clay can be easily found near the pounds, and generally, when these pounds get dry, the artisan collects this clay.

History of terracotta

Terracottas history can be traced from the Prehistoric art era; favorite products found in history were The Venus of Dolni Vestonice (c.26,000 BCE), The Thinker of Cernavoda (5000 BCE), and The Chinese Terracotta Army Warriors (246-208 BCE). It has been a great part of Chinese Pottery (from 10,000 BCE), Greek Pottery (from 7,000 BCE), and Mesopotamian and Egyptian arts and sculptures. They were also seen in Minoan art from Crete and Italian Etruscan art.

Typically terracotta was used in making decoration (architecture), sculptures of gods and goddesses, terracotta reliefs, and human figurines. Due to its lightweight nature, it has been extensively used for architectural purposes worldwide.

Types of clay

Based on its origin, clay can be divided into two categories. The first is our organic clay extracted from natural minerals, and the second is artificial clay made out of polymer.

Types of organic clays are

Earthenware – Clay, which is used for making terracotta. It is found impure in its basic state and then refined to make products out of it.

Kaolin – It is a soft white clay known as china clay. The natural state of kaolin is smooth powder consistency, white color, and consists of mineral kaolinite in it.

Stoneware – After earthenware, crockery came into frame. It is non-porous, liquid-resistant, and more durable than any other pottery.

A Complete Guide from a Terracotta Factory

Terracotta products have always been popular in home decor, gardening, tableware, and more. They are known for their natural, aesthetic texture and color, as well as their excellent breathability and durability. As a professional terracotta factory, we are dedicated to producing high-quality terracotta products. In this article, we will detail the process of making terracotta products, from selecting raw materials to the final firing of the product, so you can understand every aspect of the terracotta craftsmanship.

1. Selection and Preparation of Raw Materials

The first step in making terracotta products is selecting the right raw materials. Terracotta is a natural clay composed mainly of silica, alumina, and iron oxide. These components give terracotta good plasticity and sinterability. We typically mine high-quality terracotta clay from quarries and then screen and purify it to remove impurities.

During preparation, we store the clay indoors to maintain its moisture and flexibility. Then, we grind and mix the clay evenly to ensure the product’s texture is fine and smooth. The key in this step is controlling the clay’s moisture and density, which directly affects the quality of the subsequent forming and firing processes.

2. Forming Techniques

There are several methods for shaping terracotta products, mainly including hand molding, throwing on a potter’s wheel, mold forming, and mechanical pressing. Different forming methods are suitable for different types of products.

Hand Molding: This is the oldest method and is usually used to create unique, artistic products. Artisans mold, carve, and trim each piece by hand, giving each work a unique shape and texture.

Throwing on a Potter’s Wheel: This process involves shaping clay blocks into various forms on a potter’s wheel and is suitable for making bowls, plates, pots, etc. Throwing requires high skill, as artisans need to control the shape and thickness of the clay on a fast-spinning wheel.

Mold Forming: This involves pressing clay into molds to create products of specific shapes. This method is suitable for mass production and can maintain consistency across all products.

Mechanical Pressing: Using mechanical pressure to shape the clay is suitable for making complex products that require high precision. This method can greatly improve production efficiency and is ideal for modern large-scale production.

3. Drying

After forming, terracotta products need to be dried. The drying process is crucial to ensure the structural integrity of the final product. If not dried properly, the product may crack or deform during firing. We typically place the products in a well-ventilated drying room and control the humidity and temperature to allow them to air dry naturally.

During drying, we also need to regularly check the products’ condition to ensure there is no uneven shrinkage or cracking. If problems are found, we will make timely repairs and adjustments.

4. Firing

Firing is the most critical step in the terracotta production process. The firing temperature and time directly affect the strength, color, and texture of the final product. We typically use electric or gas kilns for firing, with temperatures ranging between 900℃ and 1100℃.

Bisque Firing: This is the first firing at a lower temperature (usually around 900℃ ) to remove moisture from the clay, making the product harder. This process causes the minerals in the clay to undergo chemical reactions, initially forming the basic structure of terracotta.

Glaze Firing: If glazing is needed, we will apply a layer of glaze to the product after bisque firing and then perform a second firing at a higher temperature (usually between 1000℃ and 1100℃ ). The glaze firing melts the glaze and fuses it with the terracotta, forming a smooth surface and rich colors.

Throughout the firing process, we need to strictly control the kiln’s temperature rise and fall rate to prevent the products from cracking or deforming due to rapid temperature changes. After firing, we let the kiln cool to room temperature before carefully removing the finished products.

5. Inspection and Finishing

The fired terracotta products must undergo strict quality inspection. We check each product for surface smoothness, color uniformity, cracks, and defects. Products with flaws will be repaired or scrapped to ensure every product that leaves our factory meets our quality standards.

In addition, for products requiring special effects, we also perform secondary processing, such as hand painting, carving, or other surface treatments, to enhance the product’s aesthetics and uniqueness.

6. Packaging and Shipping

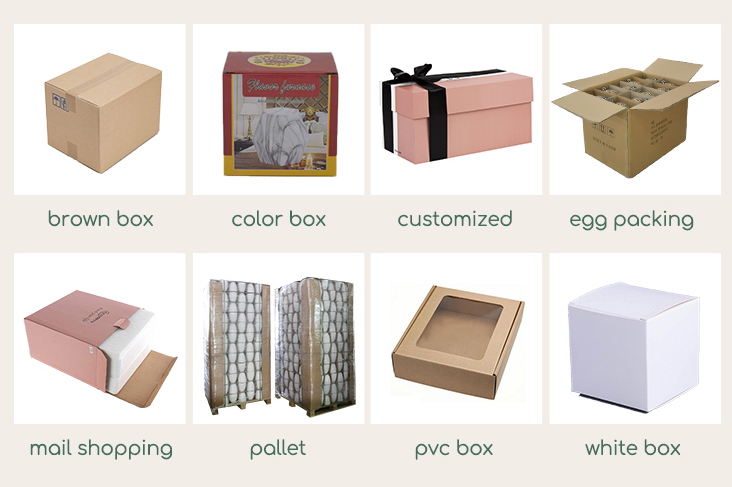

The terracotta products that have passed inspection and finishing will be properly packaged to prevent damage during transportation. We usually use foam pads, bubble wrap, and reinforced cartons to ensure that the products are not impacted or compressed during shipping.

Finally, we will load and ship the products according to the customer’s needs. We cooperate with several logistics companies to ensure the products can be safely and timely delivered to our customers.

Advantages and Applications of Terracotta Products

Terracotta products are loved for their unique natural beauty and versatility. They are not only used for home decoration but also widely used in gardening, construction, and catering.

- Home Decoration: The warm tones and rustic appearance of terracotta make it an ideal choice for decorative items. Whether it’s vases, ornaments, or lamps, terracotta products can add a touch of nature to the home.

- Gardening Applications: Terracotta pots are popular with gardening enthusiasts due to their good breathability and drainage. They help the plant roots breathe and grow, making them ideal containers for various plants.

- Architecture and Interior Design: Terracotta bricks and tiles are often used in architecture and interior design for their good thermal insulation and durability. They provide a natural aesthetic effect while also being practical.

- Tableware: Terracotta tableware, with its natural heat retention and non-toxic properties, is widely used in the catering industry. Whether plates, bowls, or baking dishes, terracotta tableware can add a touch of nature to the dining table.

Conclusion

The production of terracotta products is an art that combines traditional craftsmanship and modern technology. As a terracotta factory, we always adhere to high production standards and strict quality control, committed to providing customers with high-quality terracotta products. We hope this article gives you a deeper understanding of the terracotta production process. If you have any questions or needs regarding terracotta products, please feel free to contact us, and we will be happy to serve you.