1.Understanding Terracotta Pots

Terracotta pots, known for their earthy, rustic appearance, are among the most popular types of flower pots in the world. At Hale Planter, we specialize in crafting high-quality terracotta pots that not only complement any garden but also provide the perfect environment for plant growth. Whether you’re a large-scale retailer or an e-commerce seller, understanding how these pots are made will help you make informed purchasing decisions, ensuring you receive the best products for your business.

Terracotta, derived from the Italian word for “baked earth,” has been used for centuries in pottery and construction due to its durability and breathability. These qualities make terracotta pots ideal for both indoor and outdoor use, particularly for plant cultivation. For B2B buyers, the demand for terracotta pots continues to grow as they offer a unique blend of aesthetic appeal and functional benefits.

2.Raw Materials and Preparation

The foundation of a good terracotta pot begins with the right raw materials. At Hale Planter, we source high-quality clay from rich deposits around the world. The key to a durable and aesthetically pleasing terracotta pot lies in the clay’s composition, which typically includes minerals like kaolinite, quartz, and iron oxide. The iron content is what gives terracotta its signature reddish-brown hue. Before the clay can be used, it undergoes a thorough preparation process, including mixing with water to achieve the correct consistency. This step is crucial, as the wrong balance of materials can lead to weak or brittle pots.

For large-scale buyers, ensuring that the raw materials meet specific quality standards is critical. At Hale Planter, we prioritize quality control at every stage of the process, ensuring consistency in the final product.

3.Shaping the Pot: Handcrafting vs Machine Molding

Once the clay is ready, the next step is shaping the pots. Traditionally, terracotta pots were hand-thrown on a potter’s wheel. This method is still in use today for custom orders or smaller batches, as it allows for intricate designs and unique shapes. However, for large-scale production, we primarily use machine molding techniques.

Machine molding offers the advantage of uniformity, which is essential for B2B buyers who require consistent product sizes and shapes for retail or wholesale distribution. The clay is pressed into molds that shape the pots to the desired dimensions. Depending on the order, Hale Planter can offer custom molds to meet specific client requirements, ensuring that your products stand out in a competitive market.

4.Drying Process: A Crucial Step

Once shaped, the pots must be thoroughly dried before they can be fired. This process can take anywhere from a few days to a week, depending on the size of the pot and the humidity in the air. Improper drying can result in cracks or warping during firing, which is why at Hale Planter, we use state-of-the-art drying chambers that control temperature and humidity to ensure even drying.

This stage is crucial for buyers to understand, as pots that are not properly dried can lead to a higher rate of defects. When working with a supplier, it’s important to inquire about their drying process and the quality control measures in place to prevent these issues.

5.Kiln Firing: The Heart of Terracotta Pot Production

The firing process is what transforms soft, moldable clay into hard, durable terracotta. This step involves placing the dried pots into kilns, where they are heated to temperatures ranging between 1,000 to 1,200 degrees Celsius. The high heat vitrifies the clay, making it strong and resistant to water absorption.

At Hale Planter, we use both traditional and modern kilns, depending on the product line and client requirements. Traditional wood-fired kilns give the pots a rustic, uneven finish that appeals to certain markets, while gas or electric kilns offer more precise temperature control and consistent results, ideal for large-scale orders.

6.Surface Treatment and Finishing

Once fired, the pots can undergo a variety of surface treatments. Some pots are left with their natural finish, while others may be polished or glazed for added durability and aesthetic appeal. Unglazed terracotta pots are more breathable, making them ideal for plants that prefer well-drained soil, while glazed pots are better suited for indoor use where water retention is more desirable.

For B2B buyers, it’s important to consider the end-use of the pots when selecting the right surface treatment. At Hale Planter, we offer a range of finishing options, allowing you to customize your order based on your target market’s preferences.

Glazed pots effect

Unglazed pots effect

7.Quality Control and Testing

At Hale Planter, quality control is a top priority. Every batch of pots undergoes rigorous testing to ensure they meet our high standards. This includes strength testing, to ensure the pots can withstand handling and shipping, as well as porosity testing, to confirm the pots provide the right balance of breathability and water retention for plants.

As a B2B buyer, working with a supplier who emphasizes quality control can save you time and money in the long run by reducing the number of defective products you receive.

8.Sustainability in Terracotta Pot Production

Sustainability is a growing concern for many buyers, and at Hale Planter, we are committed to minimizing our environmental impact. Our production process incorporates energy-efficient kilns, and we source clay from sustainable deposits to ensure that our operations are environmentally friendly.

For B2B buyers, aligning with a supplier that prioritizes sustainability can be a strong selling point for your customers, particularly in markets where eco-friendly products are in high demand.

9.Packaging and Shipping for B2B Buyers

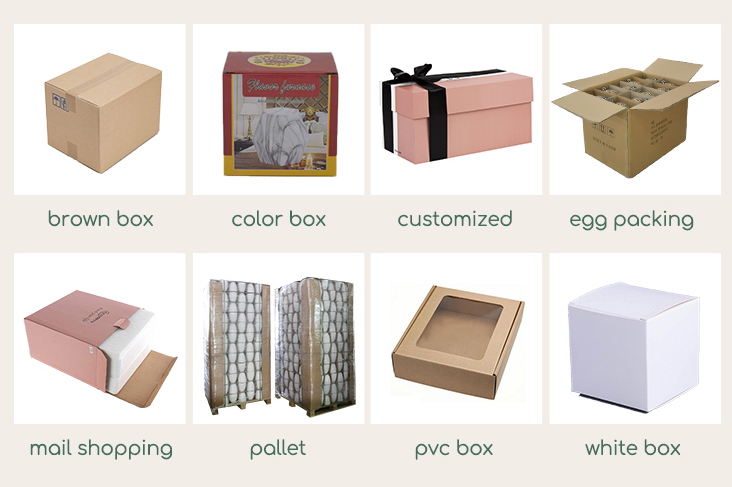

One of the challenges of terracotta pots is their fragility during shipping. At Hale Planter, we take extra precautions to ensure that our products arrive at their destination in perfect condition. This includes custom packaging solutions that minimize the risk of breakage, as well as efficient shipping methods that reduce costs for our clients.

For large-scale buyers, shipping costs and product safety are major concerns. By partnering with a supplier like Hale Planter, you can be confident that your products will arrive safely and on time, regardless of the destination.

10.How to Choose the Right Supplier: What Sets Hale Planter Apart

When selecting a terracotta pot supplier, it’s important to consider factors like product quality, consistency, and customer service. At Hale Planter, we pride ourselves on offering all three. With years of experience in the industry, we understand the needs of B2B buyers and are committed to providing top-tier products and services.

Conclusion: Investing in High-Quality Terracotta Pots for Long-Term Profitability

Terracotta pots are a timeless, versatile product that appeals to a wide range of consumers. By understanding the manufacturing process and selecting a supplier that prioritizes quality and sustainability, B2B buyers can ensure long-term profitability. At Hale Planter, we are dedicated to helping our clients succeed by providing high-quality terracotta pots that meet the demands of today’s market