Flower pots are essential for the global gardening and landscaping industry. Whether you are a large-scale supermarket chain or a small-batch e-commerce seller, understanding how flower pots are made helps you make more informed purchasing decisions. This article explores the entire flower pot manufacturing process, from selecting the right raw materials to customization options and quality control. Additionally, we will highlight the top 10 flower pot manufacturing factories worldwide to assist you in your procurement decisions.

At Hale Planter, we specialize in high-quality flower pots, offering ODM (Original Design Manufacturing) services for large-scale purchasers and OEM (Original Equipment Manufacturing) services for smaller orders. Our team is committed to providing customized and sustainable solutions for global buyers.

1. Raw Material Selection

The first step in manufacturing flower pots is selecting the appropriate raw materials. The type of material used impacts the pot’s durability, water retention, breathability, and overall aesthetic.

Common Materials for Flower Pots:

- Terracotta (Clay): Known for its excellent breathability, terracotta is ideal for plants that require good air circulation. It’s often used in outdoor gardens.

- Ceramics: Ceramic pots, often glazed, are less porous and more decorative. These are popular for indoor use due to their ability to retain moisture.

- Plastic: Lightweight, durable, and cost-effective, plastic is a preferred choice for mass production and outdoor use.

- Metal: Metal pots are used more as decorative covers due to their poor breathability and heat retention.

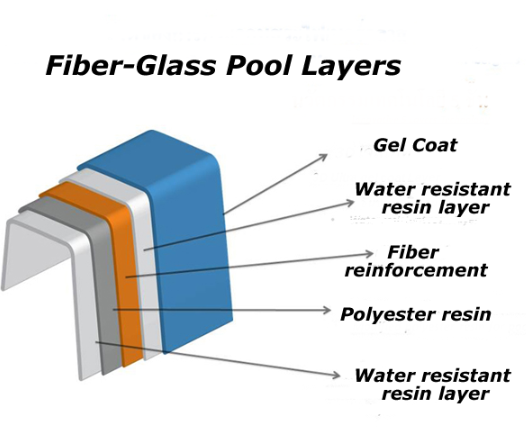

- Fiberglass: A newer, modern option, combining durability with a lightweight structure, making it ideal for both outdoor and decorative purposes.

Material Comparison Table

| Material | Breathability | Durability | Weight | Cost | Best Use |

|---|---|---|---|---|---|

| Terracotta | High | Moderate | Heavy | Moderate | Outdoor and indoor plants |

| Ceramics | Low | High | Heavy | High | Decorative indoor pots |

| Plastic | Low | High | Light | Low | Mass production, outdoor |

| Metal | Low | High | Heavy | High | Decorative covers |

| Fiberglass | Low | High | Light | High | Outdoor use, modern look |

2. Molding and Shaping

Once the raw material is selected, the next step is to mold and shape the flower pots. The method depends on the material being used.

- Terracotta and Ceramic Pots: These are typically made using slip casting or wheel throwing. Slip casting involves pouring liquid clay into molds, while wheel throwing shapes the pot using a spinning wheel. Once formed, the pots are left to dry.

- Plastic Pots: Plastic pots are made through injection molding or rotational molding, which allows for mass production at a low cost.

- Metal and Fiberglass Pots: These are created using sheet metal forming and fiberglass layering techniques, respectively.

3. Drying and Firing (For Clay and Ceramic Pots)

After shaping, the pots need to be dried before firing. This step ensures moisture is removed to prevent cracks during firing.

- Drying: Clay pots are air-dried for several days, depending on their thickness and size.

- Firing: After drying, the pots are fired in kilns at temperatures between 1000°C and 1300°C. This hardens the material and gives it strength. Ceramic pots typically undergo a second firing if they are glazed.

4. Glazing and Finishing

Glazing adds a protective and decorative layer to ceramic pots. After the initial firing, a glaze is applied, and the pots are fired again to fuse the glaze to the surface. Plastic pots may undergo finishing processes like painting or UV coating.

At Hale Planter, we focus on eco-friendly glazing and finishing methods that minimize waste and meet environmental standards.

@haleplanter Dice flower pots in production #planters #ceramicplanter #homedecor #flowerpot🏺⚱️💐💐 #diyterracottaplanters #diyplanter #gardening #gardenpots #plantpots🌱

♬ Flowers – Miley Cyrus

5. Quality Control

Quality control is a critical step in the manufacturing process. Every pot is checked for:

- Structural integrity: Ensuring there are no cracks or weak points.

- Aesthetic uniformity: Checking for consistency in color, shape, and glazing.

- Functional testing: Water retention and drainage are tested to ensure the pots meet their design specifications.

At Hale Planter, each pot undergoes multiple rounds of inspection to ensure we deliver high-quality products to our B2B clients.

6. Customization and Design Options (ODM and OEM Services)

Customization is a key aspect of flower pot manufacturing, especially for B2B buyers.

- ODM Services: We offer original designs that can be tailored to your specifications, including unique shapes, colors, and branding.

- OEM Services: We provide private label manufacturing for smaller orders, allowing buyers to personalize existing designs with their logos and colors.

Our team of designers works closely with clients to create pots that are both functional and aesthetically pleasing.

7. Packaging and Shipping

Once the pots are completed, they are packed and prepared for shipping. We offer:

- Bulk packaging: Ideal for large orders to optimize shipping.

- Retail-ready packaging: Customized for store display.

- Eco-friendly options: For clients looking for sustainable packaging solutions.

Pots are shipped via sea or air, depending on order size and destination.

Top 7 Flower Pot Manufacturing Factories Worldwide

For global buyers, understanding which manufacturers provide reliable and high-quality products is essential. Below are ten of the leading flower pot manufacturing factories, excluding brands, that offer robust production capabilities.

1. GGP International (Italy)

GGP International focuses on high-quality ceramic pots. Their modern production facilities enable large-scale manufacturing with a focus on premium, decorative flower pots for the European market.

2. Grupo Solana (Mexico)

Grupo Solana is one of Mexico’s largest manufacturers of terracotta pots, with a focus on exporting to North America and Europe. Their products are known for durability and aesthetic appeal.

3. ARTEVASI (Portugal)

ARTEVASI produces plastic and ceramic flower pots for global markets. The company uses innovative designs and eco-friendly materials, making it a favorite among environmentally conscious buyers.

4. Plastecnic (Spain)

One of Europe’s largest manufacturers of plastic flower pots, Plastecnic offers a wide range of styles for both indoor and outdoor use. They specialize in mass production for large retailers.

5. Jelenia Plast (Poland)

Jelenia Plast focuses on high-quality plastic pots and planters. With advanced molding technology, they can meet large-scale production needs for global retailers.

6. Sembcorp Utilities (Vietnam)

Sembcorp Utilities is a major player in the Southeast Asian market, focusing on plastic and fiberglass pots. Their state-of-the-art facilities enable them to produce large volumes efficiently.

7. Steenfabriek Joosten (Netherlands)

This Dutch company specializes in terracotta and ceramic pots. Their expertise in traditional production techniques is highly valued in the European market.

Conclusion

The process of flower pot manufacturing involves multiple steps, from selecting raw materials to molding, firing, glazing, and quality control. Each material has its advantages, and the choice depends on your specific needs, whether it’s durability, breathability, or aesthetics.

At Hale Planter, we specialize in providing high-quality flower pots for B2B buyers, offering both ODM services for large-scale orders and OEM options for smaller quantities. Our commitment to quality and sustainability ensures that our pots not only look good but perform well in a variety of settings.

Whether you’re looking for large-scale production for supermarkets or custom designs for boutique e-commerce stores, Hale Planter is your trusted partner for all your flower pot manufacturing needs. Contact us today to learn more about our customizable solutions and how we can help your business grow!